Energy Infrastructure – Gas Compression Station in Bakken Shale Field Utilizes Ground Access Unit for Rich Burn Engines

Situation

In early 2019, a gas compression station in the Bakken Shale Field was setting up new gas compression equipment in the North Dakota Bakken Shale Field based on the need for increased gas gathering and gas processing. Over the coming years, the customer would have a need for multiple 2,000+ HP units across more than four sites. The customer needed a standardized unit that could be supplied by multiple gas packagers either from the USA or Canada to meet this demand.

Challenges

Due to limited engine availability, tight delivery requirements, and various local permitting challenges, the customer opted to utilize the Waukesha 9394GSI rich burn engine as the preferred packaged solution instead of their historic use of lean burn engines. Additionally, the customer increased its analysis of environmental impacts requiring a larger focus on dispersion air modeling and Hazardous Air Pollutants (HAPs) such as Formaldehyde. These changes caused the application to call for a higher than desired stack height for the emissions package, which made a cooler-mounted catalytic converter insufficient. Based on normal wind velocities in this region, the catalytic converter would also need to be securely mounted to a concrete pad.

Solution

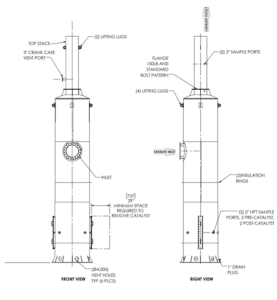

After being approached by the customer, the MIRATECH team envisioned a different approach. By utilizing its innovative Ground Access product design typically targeted toward lean burn engines, MIRATECH could overcome these design considerations and satisfy the customer. In this application, the emission reductions of Nitric Oxides (NOx), Carbon Monoxide (CO), Non-Methane, Non-Ethane Hydrocarbons (NMNEHC), and Formaldehyde (HCHO) would require a greater catalyst volume and specific need for catalyst sealing. This approach is different than what had been utilized by the customer in the past.

Through custom engineering and decades of experience working in these applications, MIRATECH designed and offered a Ground Access solution for this rich burn application. The solution met the stringent emissions and sound targets while also providing ease of installation. The design provided ground level access to catalysts for easier maintenance, therefore eliminating the need for additional costly steel structures typically provided for catalyst access. Furthermore, the MIRATECH design provided a lot of flexibility for stack height, wind rating, sound attenuation, inlet height, etc. This design ultimately allowed the customer to have a solution that matched its package requirements without significant changes to the design.

Conclusion

Continued lowering of emissions targets and CO2e requirements by local permitting authorities will require customers to consider different strategies. The MIRATECH design team uses a consultative approach with the customer to apply existing and forward-looking technologies to current applications, oftentimes yielding new innovative approaches.

In the gas compression space, retrofit and new build projects with space limitations are becoming more prevalent globally. It is more important than ever to have a partner who can provide knowledge from previous installations and design experience. With MIRATECH, you are choosing a partner who can design custom solutions based on project constraints that will help the end user meet their needs.