Industrial – OEM Manufacturer of Sewer Trucks and Excavation Equipment Mandates Machines to be Quieter during Operations

Situation

A United States based original equipment manufacturer of industrial hydro excavation equipment recently identified a requirement to reduce noise from their machines during operation. They were not satisfied with the acoustic performance they were achieving from their current silencer supplier, and they knew they had to improve to have a market-leading product.

Once connected with MIRATECH, the Sales & Engineering teams worked closely with the customer to define the scope of the project by identifying data collection and testing methodology. They also worked through design considerations for the competing goals of increased acoustic performance, space claim, weight limitations, and cost targets.

Challenges

Positive Displacement Blower sound levels can be very high. In addition, there are low frequencies or dominant tones to the raw sound that can be disturbing to surrounding receptors if not attenuated to a suitable level. Furthermore, the collection of raw blower sound levels is uncommon and would need to be confirmed for use in any analysis of potential new silencer designs.

Solution

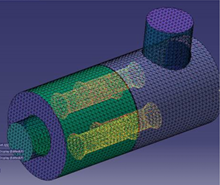

Within the given constraints, the MIRATECH Engineering team employed a range of 3D acoustical modelling techniques. Through its broad and detailed experience in combination with advanced software, the MIRATECH team performed analysis on several potential improved silencer designs. An example of one such analysis can be seen in the following graph, detailing a noted improvement in 31.5 and 63 hz bands.

Additionally, CFD modelling was employed to streamline the flow conditions internally of the silencer, thereby minimizing flow restriction and turbulence through various acoustic elements. This allowed the solution to avoid the potential design pitfalls of flow generated noise or excessive silencer backpressure.

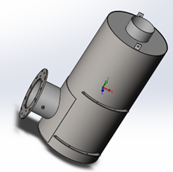

Following confirmation of a suitable design candidate for prototype testing, MIRATECH furnished a sample silencer to the client for benchmark testing and confirmation of mechanical interfaces. Prototype testing, which includes fit-up, acoustic performance, and backpressure measurements, were all conducted at the client’s facility on a production Hydro-excavator.

Conclusion

By increasing the silencer’s acoustic performance greater than 10 dBA and by shifting the peak acoustic frequency, the new silencers were deemed a suitable candidate for replacement of the older models.

Following the performance of all relevant tests, the design team completed the required follow-up analysis and confirmed all commercial details. The client then informed MIRATECH of their selection for intake and discharge silencers for each of their truck lines. The silencers MIRATECH supplied were the right solution for the customer application.

MIRATECH is pleased to be able to help manufacturers of industrial equipment improve their standard products by working to introduce high performance silencers that reduce noise and have a positive effect on our environment.