International – BlmSchV44 Compliance on a Data Center

Situation

In late 2020, MIRATECH was engaged by a German engine distributor to comply with the 44. BImSchV regulation on 18 Caterpillar diesel engines. The emissions targets the customer desired to achieve were as follows:

- NOx < 500 mg/ Nm3 @ 5% O2,

- NH3 < 30 mg/ Nm3 @ 5% O2, and

- Lp < 85 dB(A) in 1 m.

The site was in Frankfurt, Germany, and the customer would be using these engines for standby power for a Data Center.

Challenges

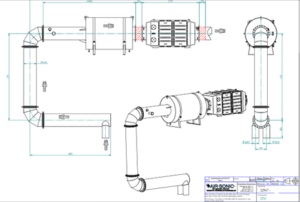

With this project, the use of an SCR and silencer were both required. Space constraints in the building made MIRATECH think outside the box to deliver a very customized solution from turbo to stack. The team knew that a traditional exhaust piping to silencer design to mixing section to SCR housing layout would be restrictive, so the team started to consider how it could shorten the solution but still provide high performance via both SCR and silencing capabilities.

Solution

To meet the customer’s tight space constraints, sound targets, and emissions targets, the MIRATECH team developed and fully integrated a urea mixing section together with a silencer. Next, MIRATECH and the customer decided to include the complete scope of supply from the engine outlet in MIRATECH’s scope of work. This included dual outlets, various piping, and elbows, all leading to the mixing section/silencer system followed by the SCR housing.

By developing this solution, it allowed the total length of the exhaust solution to shorten considerably. As a result, the customer was presented with a much more cost-effective solution than traditional methods of a separate silencer and mixing section.

To give the customer additional peace of mind, MIRATECH ensured it offered a suitable warranty on the backpressure, sound, and emissions targets with its final design.

Conclusion

The design collaboration and partnership between MIRATECH and its customer led successfully to the commissioning of these 18 engines in late 2021. Both the customer and the data center end user are very pleased with the solution, and it has become a best practice for that end user going forward. All sound and emissions targets were achieved, and compliance with the 44. BImSchV regulation was assured.

Separately from this project, this customization of an integrated silencer and mixing section led MIRATECH’s R&D team in further product development for other global markets. A few months following the commissioning of these units, MIRATECH introduced the NOx Box to the USA market, an integration solution for both sound and NOx reduction all in a single, compact box.

MIRATECH not only sees customizing a design for a client as beneficial locally for the immediate project at hand, but also takes a long-term view of the advantages of customization for a global company with global clients.