Energy Infrastructure

MIRATECH supports critical applications in the energy infrastructure market, including:

- Field gathering

- Midstream/processing

- Interstate pipelines

- Storage and cryo plants

- Gas turbines

Our diverse customer base includes original equipment integrators and packagers; NG midstream, processing and pipeline companies; and engineering and construction companies. In addition to our innovative products, our customers rely on our expertise in navigating today’s regulatory market, which includes:

- GP5a

- JJJJ (Quad J)

- YYYY (Quad Y)

- ZZZZ (Quad Z)

- California Air Resources Board (CARB)

- Ozone changes within National Ambient Air Quality Standards (NAAQS)

- U.S. State Implementation Plans

- FREC regulations for both emissions and sound

- Canadian Province Standards

- World Bank Standards

- T.A. Luft Standards

We provide engineered emissions-control solutions not only for natural energy infrastructure stations in transmission pipeline systems, but also more broadly for RICE engines at the wellhead throughout the entire value chain:

- HP solutions from 20 to 20,000+

- Sound attenuation from 15 to 60 dBA

- Up to three-year guaranteed emissions reductions (with the Apex catalyst integration)

Our catalytic reduction systems can reduce pollutants for any stationary reciprocating natural gas, diesel or dual-fuel engine:

- NOx up to 99% with SCR

- CO up to 98%

- Hazardous air pollutants (HAPs) up to 99%

- Volatile organic compounds (VOCs) up to 85%

MIRATECH Fabrication Capabilities

- Emission controls

- Exhaust heat recovery

- Engine exhaust and intake silencers

- Interconnecting piping

MIRATECH customized energy infrastructure systems are engineered to perform in highly demanding environments, including:

- Extreme wind speeds and shears

- Altitude

- Space limitations

- Ambient temperature swings

- Humidity variations

- Tight noise requirements

- Seismic location and codes

- Air permit requirements

Core Products and Integrated Systems

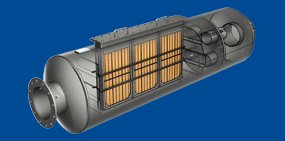

MIRATECH Quad-Tuned Silencers

- Field-tested up to 60 dBA attenuation, for high sound requirement application

- Patent-pending chamber design with quadruple-tuned components

- Design algorithm allows tuning of muffler to match specific engine environment and application

- For both horizontal and ground access designs

- Higher sound attenuation than multiple silencers in a series; reduces exhaust leak risk

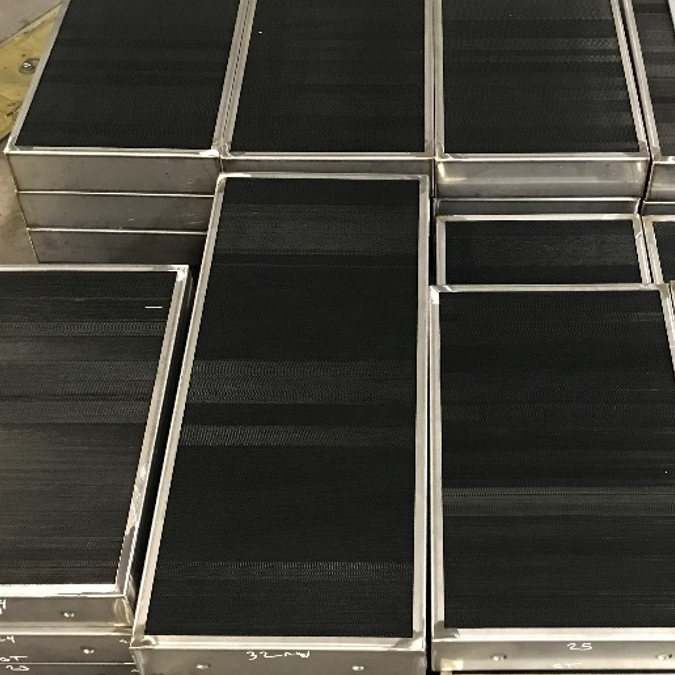

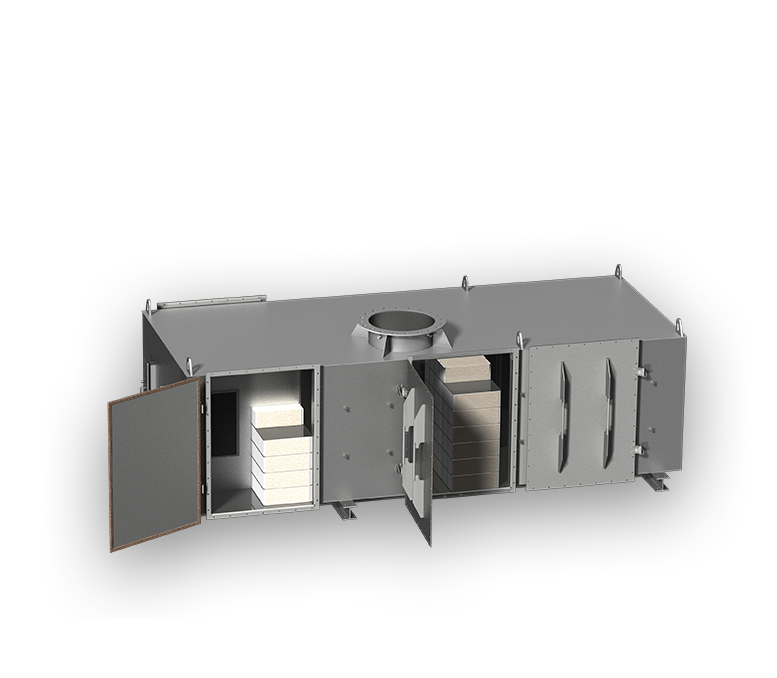

MIRATECH Z-Flow Emission Solution

- Catalyst housing for high emissions reduction targets and site HP growth needs

- Paralleled single-layer catalyst design improves exhaust flow and lowers back pressure

- For lean-burn NG engines from 1,400 – 5,000 HP

- Available in both perimeter and face seal (EZ line) options

- Customizable for noise control: ZCS: 22-25 dBA; ZHS: 27-35 dBA; ZES: 45-52 dBA

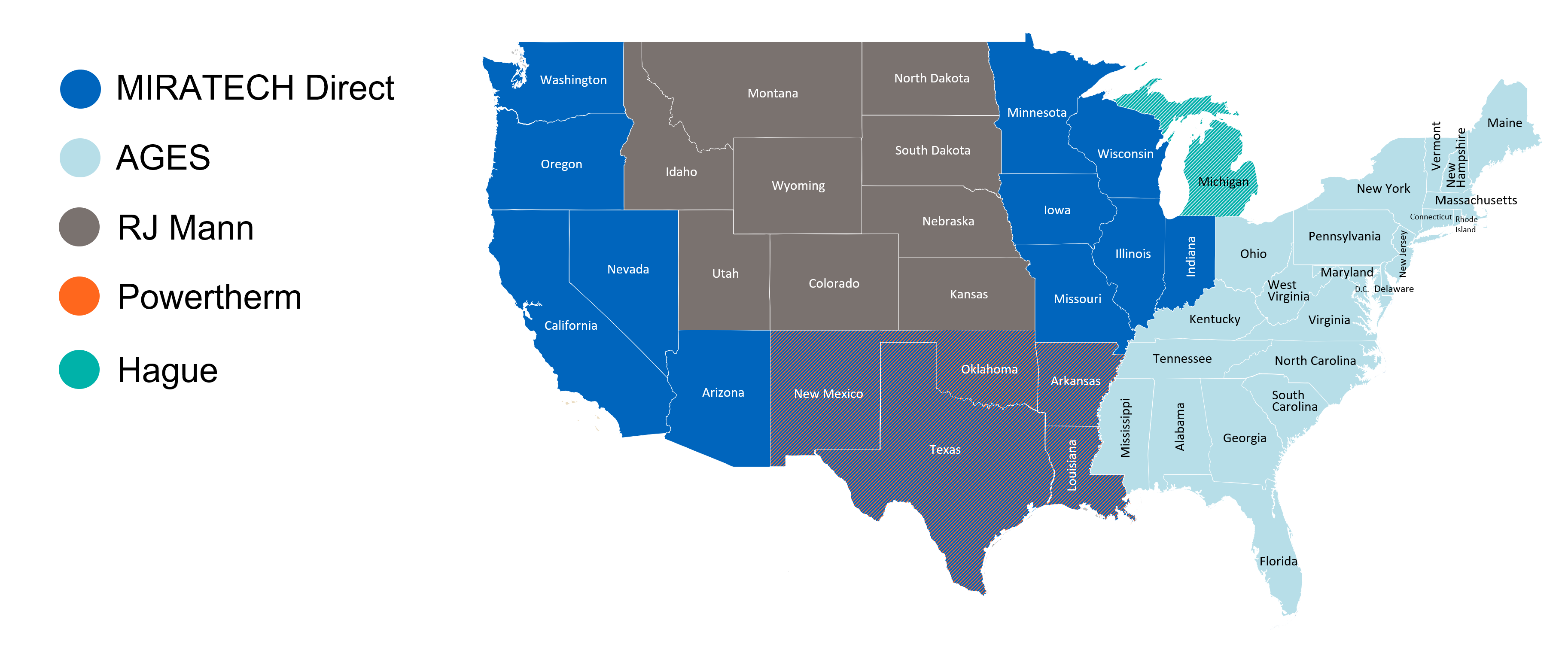

Energy Infrastructure Market Reach – Authorized Distributor Partnerships